It is one of the longest tunnels of the AVE on its way through Galicia, 8.1 kilometers length.

URDIN T is made from virgin resins, environmental sustainable.

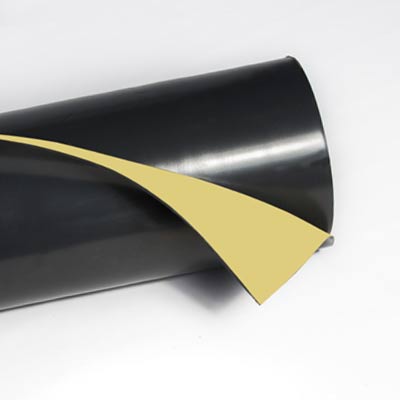

SINTEC has been the company in charge of the waterproofing of one of the longest tunnels in the Galician AVE, the one in El Espiño, with its URDIN T material, a sheet of Flexible Vinyl Polychloride (PVC-P). This stretch of 8.1 kilometers is located between the municipalities of A Gudiña and Vilariñio de Conso in Ourense and belongs to the Zamora-Ourense section of the high-speed line between Galicia and Madrid.

The participation of SINTEC in one of the most important works in the connection of Galicia with the plateau endorses this Company as a high quality supplier in the waterproofing of large-scale works. In fact, SINTEC has also been in charge of the same type of action in the Portela AVE tunnel, in the province of Pontevedra, among some others.

This type of material, manufactured under the EN 13967 and EN 13491 Standards, is used for the waterproofing of all types of underground structures and cut and cover tunnels. URDIN T is made exclusively from virgin resins, which guarantee constant characteristics and optimum durability.

Among its main advantages, its resistance to puncture, swelling, putrescibility, microorganisms and aging can be mentioned. In addition, it has a high level of tightness, even under permanent deformation, and is stable in aqueous solutions with PH 12-13.

Due to its characteristics, the material used in the El Espiño tunnel, in addition to excellent mechanical properties, has withstood all types of inclement weather during its installation. In this phase, the signal layer Signal Layer has made possible the visual detection of any possible damage caused.

Flexible Vinyl Chloride membranes are hot air welded, even after several years after installation, and can be manufactured in any length, according to the tunnel arch dimensions. The manipulation of the material and its extension can be carried out at temperatures of even 0 ° C, although SINTEC recommends its application at a minimum temperature of + 10 ° C.

At the time of installing the membrane, the operators must make sure that the support is dry, clean and free of sharp elements. Later, they weld the membranes wit a double channel, in order to check the correct welding by means of air pressure test.

In its commitment to the environment, SINTEC has sustainable products. In fact, URDIN T membranes are a totally recyclable product.

The excellent results of its materials and the placement of them by experienced and approved professionals has given SINTEC the confidence to offer waterproofing solutions in large infrastructures